Construction Techniques

Precast Concrete Building Systems

Precast Concrete

There are different types of precast concrete buildings, which can be grouped as total precast, partial precast and mixed construction structures. It is necessary to study each system for a better understanding and to arrive at an appropriate application. Total precast building comprises various precast components such as footings, beams, slabs, columns, walls, facades etc. A partial precast buildings can be made of the precast components and cast in place concrete members. This type of building is also known as hybrid construction. Mixed construction buildings consist of precast components along with CIP concrete or steel or masonry or timber members.

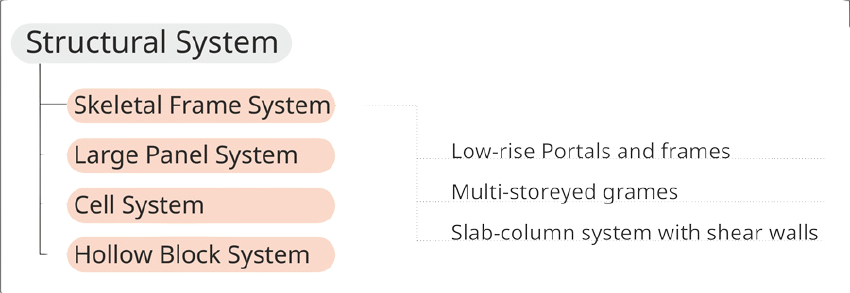

The different system of precast concrete buildings can be grouped under the following headings-

- Overall structural systems

- Systems for lateral load resistance

- Floor and roof system

Overall structural systems

The structural system of a building is that part of the building which resists the oads acting on the building. It can be broadly categorised under four groups as discussed below.

Skeletal frames

Skeletal frames are commonly used for relatively low-rise buildings which do not have many partitions. A common usage is in large-scale car parking buildings. Other common buildings built using frames are office buildings and commercial buildings. The frames can be designed as moment-frames and often are either combined with precast shear wall systems or cast-in-situ shear walls. The speed of construction and the high quality of the components are the main benefits of using precast skeletal systems. A building using a fully precast system can often be built at approximately 10-14 days per floor depending on the area and logistic limitations. The frame system can be designed for resisting lateral loans. However, there may be a need for supplemental lateral loan resistance through the use of braces or walls. Hence, core or shear walls are provided.

It incorporates a network, or system, of columns and connecting beams which support the building’s interior floors and exterior walls and carries all loads to the foundations. Skeleton frames can be constructed from timber, concrete or structural steel components, with the building envelope formed by glazing, brick, cladding and so on hung on the outside.

The skeletal frame was introduced in the late-19th and early-20th centuries, and allowed for the rapid erection of buildings, such as the early skyscrapers. It enabled interior floor layouts to be free of immovable walls, making them more flexible spaces, and meant that different materials could be used for the facades. This had the effect of reducing the importance of masonry from something that was a structural element to having a more decorative role.

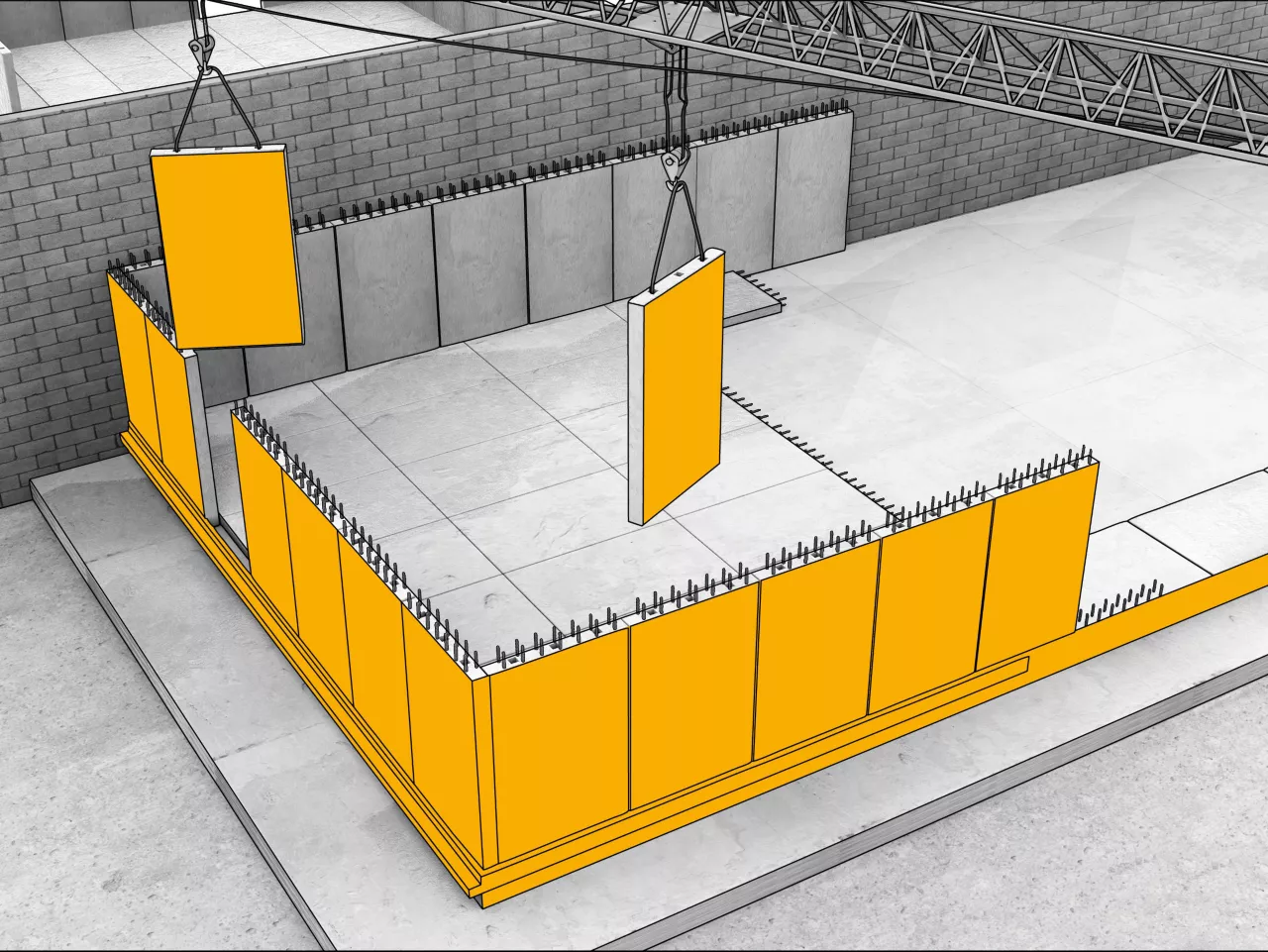

Large Panel system

Large-panel structures are one of the most progressive industrial types of structural elements. In modern construction they are used in building apartment houses, public and industrial buildings, roads, air-fields, dams, and canals. They have become most widespread in large-scale housing and civil construction, where the erection of buildings from large panels manufactured at housing construction combines and plants makes possible a reduction in construction time by a factor of 1.5–2.0 in comparison with erection of the buildings from brick or other traditional materials, as well as a decrease of 30-40 percent in labor expenditures at the construction site.

All the main parts of a building, including exterior and interior walls, floor slabs, roofs, and staircases, may be made up from large-panel structures. Large-panel structures are used in two main design schemes, frame-panel and panel (frameless) buildings. In frame-panel buildings, all the base loads are borne by the building’s frame, and the panels are usually used to fill the frame and as enclosure elements. Frameless buildings are assembled from panels that perform the load-bearing and enclosing functions simultaneously.

Large-panel structures for exterior walls consist of panels one or two stories in height and one or two rooms in width. The panels may be blind (without openings) or with window or door openings. In terms of design, the wall panels may be single-layer (solid) and multilayer (sandwich).

Solid panels are manufactured from materials that have insulating properties and at the same time can perform supporting functions-for example, light-weight concrete, cellular concretes, and hollow ceramic stone. Sandwich wall panels are made with two or three layers; their thickness depends on the climatic conditions of the region and the physico technical properties of the materials used for the insulating layer and for the exterior (supporting) layers. The exterior layers of the panels are usually made from heavy, light-weight, or solid silicate concrete or from brickwork or sheeting (asbestos cement, steel, or aluminum). Polystyrene foam, rigid and semirigid rock wool panels, or cellular concretes may be used for the insulating layer.

Wall panels are produced in completely finished form, with ready-to-paint surfaces and with windows and doors; the piping for heating and other systems and for wiring may also be installed in the panels.

The surface of exterior wall panels is covered with decorative mortar or is faced with ceramic or other finishing tiles. After assembly, the joints between panels are filled with mortar or with lightweight or ordinary concrete and then sealed with elastic packing and special mastics.

The large-panel roof elements are used in housing and public buildings mainly in the form of combined atticless roofs, and in industrial buildings the roof panels have a span of up to 12 m. The weight of large-panel structures depends on the method of dividing the building into prefabricated elements; it is usually 1.5–7.5 tons.

Cell/Box system

Orthogonal walls and slabs are cast together as integral units to create box type structure. As with carcass construction or prefabricated structures with load-bearing wall panels, modular box unit systems are composed of a combination of rods or surface load-bearing elements. The basic problem in the modular box unit construction system is how to join the individual box together. The tolerances between the individual box units are essential. Box units systems are highly advanced as to the industrialization of building construction, in other words, they are systems with a high level of industrialization. Box units are three dimensional spatial elements formed by the combination of wall panels and floor units. These systems, constituting an advancement of heavy and light-weight panel systems, are being preferred to achieve a high degree of completion through factory manufacture of the product, i.e. the building. The development of the box unit system makes it possible to manufacture an entire completed product in the factory.

“Box-module structures” are buildings with a fireproof and permanent design in steel and concrete construction. Here the entire structure is factory-built, then split into modules, and transported to the construction site.

The development of the box system makes it possible to manufacture an entire completed product in the factory. “box-module structures” are buildings with a fireproof and permanent design in steel and concrete construction. Here the entire structure is factory-built, then split into modules, and transported to the construction site. Today, box systems find application in increasingly diverse fields, since the employment of such systems in construction is associated with advantages such as cost reduction, quick mounting, timely completion of works, and minimization of material losses, thus serving to create higher-quality physical spaces.

Block system

Precast blocks with a rectangular or quadrangular prism shape contain a normal weight hydraulic concrete casing, lightweight concrete or similar material, for building walls or slabs. The steel-reinforced blocks for walls, mezzanine or rooftop slabs have the length of the wall or slab to build. An acoustic, thermal-insulating lightweight material housed in the interior simultaneous provides for blocks sufficiently lightweight to transport and install manually on-site. For walls, the blocks are tongued and grooved on the top and bottom sides and placed horizontally one on top of the other using block or similar adhesive therebetween. In the corners or „T“ intersections, blocks are alternatively placed and form armed headframes for stability and resistance. For blocks for slabs, the tongue and groove system is on the sides, installed one beside the other, using block or similar adhesive there between. Transversal rods to the slab are placed to avoid temperature retraction.

System for lateral load resistance

Natural hazards like earthquakes cause damage to or collapse of buildings if not designed for lateral loads resulting due to Earthquakes. Hence for seismic resistance for high rise structures it is important to provide exclusive Lateral Load Resisting System (LLRS) which will supplement the behavior of moment resisting frames in resisting the lateral load. The dual structural system consisting of special moment resisting frame (SMRF) and concrete shear wall has better seismic performance due to improved lateral stiffness and lateral strength. A well designed system of shear walls in a building frame improves its seismic performance significantly. Steel bracings are also one of the successful lateral load resisting systems. The use of steel bracing systems for strengthening or retrofitting seismically inadequate reinforced concrete frames is a viable solution for enhancing earthquake resistance.

Portal frames

Portal frames are generally low-rise structures, comprising columns and horizontal or pitched rafters, connected by moment-resisting connections. Resistance to lateral and vertical actions is provided by the rigidity of the connections and the bending stiffness of the members, which is increased by a suitable haunch or deepening of the rafter sections. This form of continuous frame structure is stable in its plane and provides a clear span that is unobstructed by bracing. They are very efficient for enclosing large volumes, therefore they are often used for industrial, storage, retail and commercial applications as well as for agricultural purposes. This article describes the anatomy and various types of portal frame and key design considerations.

Multi-storey steel frame structure

Multi-storey steel frame structure consists of beams and columns from welded H-shaped steel, hot-rolled H-shaped steel. In these frames, the beam and column system takes the gravity load such as dead and live loads. Now steel frame structure is mostly used for residential, commercial, institutional buildings all over the world.

In developed countries a very large percentage of multi-storey buildings are built with steel structure. Steel is not so commonly used in construction of multi-storey frame, but it is a better material than reinforced concrete. The use of steel in multi-storey building construction results in many advantages for the builder and the user.

Wall system

Precast walls are energy efficient due to a high thermal mass that enables materials to absorb and store temperatures at a more constant rate. With this system, it reduces the fluctuation of temperatures within the building. Since precast wall panels are manufactured in a production facility, the impact that these panels impose onsite is minimal. This helps reduce the space needed on a job site. Precast wall panels can be customized to the architect’s or owner’s desire. Some architectural features that can be found in a wall panel system include bullnoses, reveals, chamfers, and a vast assortment of form liners.

Maintenance may include occasional cleaning and possibly maintaining the caulk joints over several years. With a precast wall panel system, very little maintenance is needed over its life span. Whether it be an interior or exterior wall panel system, these systems can be installed in a quick process without involving multiple trades. By eliminating the use of other trades, a wall panel system can decrease the overall cost of the project.

Roof and Floor system

The roof and floor systems are described separately to illustrate the transfer of loads between the several components.

Roofing system

Concrete roof systems have three basic advantages over competitive materials- esthetic appeal, structural economy and functional utility. Double-tees are the most widely used prestressed concrete product in the minimum-span range. Double-tees may be used for many types of buildings. They are very economical, readily available, easily shipped and erected and contribute to early building occupancy.

Troffers formed by the stems may be used for air ducts or lighting systems. Hollow-core slabs provide minimum depth with a flush ceiling. They are available as custom precast concrete products or are sold under several trade names.

Since their production is highly industrialized, their cost is low. Single-tees are the giants of the precast, prestressed concrete industry. They are used to provide spans ranging from 30 to 100 feet. Longer spans are practical with special design considerations or cantilevered ends. Flange widths range from 4 to 10 feet, although the 8 foot wide section is the most commonly used. Depths range from 12 to more than 36 inches. Attractive and economical roof decks can be formed by using prestressed concrete joists in combination with prestressed planks. The keystone joist may be obtained in depths of 6 to 18 inches and the tee joists in depths of 8 to 20 inches. Joists may be handled with light equipment and they work well with bearing wall construction. Joist and plank construction provides an attractive finished ceiling with excellent acoustical qualities and lighting efficiency.

Floor System

There is a great need for a durable precast concrete floor structure that is lighter, stronger and more energy efficient, and one that can be manufactured in variable sizes. To help reduce flooring weight for transportation, erection and foundation loading, precast concrete planks are cast with continuous circular voids running through the panel’s length. For added strength, prestressing strands are cast into the panels during production. With its top and bottom longitudinal flanges, hollowcore is an exceptionally strong structural component that is used to span large areas between building columns and walls.